Automatic labeling machine requirements for labels

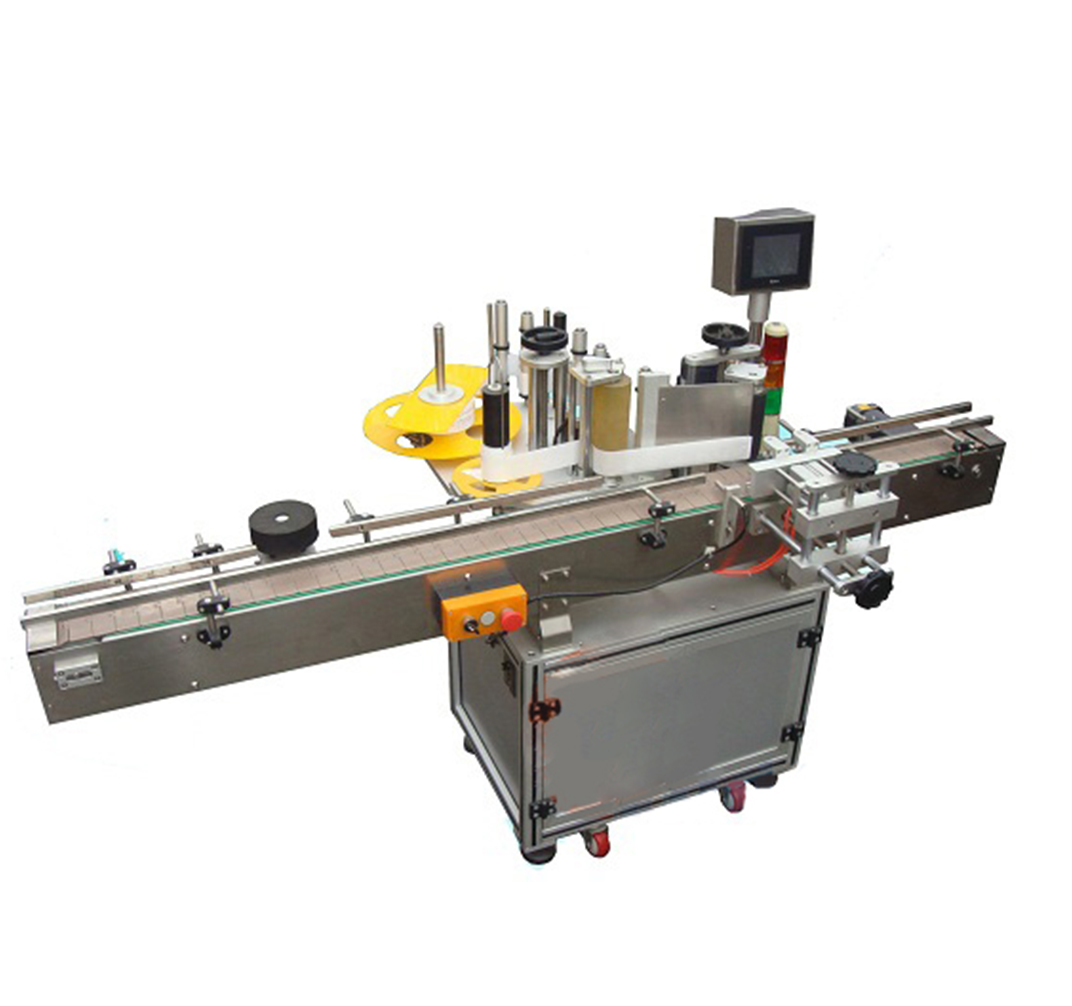

When the sensor sends a signal that the labeled object is ready to be labeled, the driving wheel on the labeling machine rotates. As the roll label is in tension on the device, when the backing paper is tightly attached to the peel-off plate to change the direction of operation, the label is forced to detach and prepare for labeling at the front end due to its own material with a certain degree of stiffness. At this time, the labeling object happens to be located in the lower part of the label, under the action of the labeling wheel, to achieve synchronous labeling. After labeling, the sensor below the roll label sends a signal to stop running, the drive wheel is stationary, and a labeling cycle ends. No matter which type of labeling machine, the labeling process is roughly similar, the difference is: the installation position of the labeling device is different, the labeling object delivery method, positioning methods and the form of labeling rollers are different.

1. Surface material

Label stiffness is the key to the label, so the surface material is required to a certain degree of strength and hardness, the label stiffness and material thickness and label area, so the use of soft film material, to increase its thickness, generally controlled at 100μm or more. Thin paper-like materials, such as 60 ~ 70g/m2 labeling paper, generally not suitable for large labels, but suitable for processing into small labels, such as the price tag used on the price tag gun. Poor firmness of the label will lead to labeling when not out of the label, or label with the backing paper rewinding, so that the automatic labeling failure.

2,. Release force

Also known as peel-off force, it is the force at which the label breaks away from the backing paper. The release force is related to the type and thickness of the adhesive and the silicon coating on the surface of the backing paper, as well as the ambient temperature during labeling. If the peeling force is too small, the label will easily fall off (from the backing paper) during transportation; if the peeling force is too large, the label will be difficult to leave the backing paper and cannot be released. Should be a comprehensive control of the technical indicators, so that the clamping force in a reasonable range.

3. Backing paper

Is also an important indicator to control the automatic labeling machine. Requirements for the base paper surface silicon coated uniform, consistent release force; uniform thickness, good tensile strength, to ensure that the labeling does not break; uniform thickness, good light transmission, to ensure that the sensor correctly identify the location of the label.

4. Processing quality

Require the backing paper to be flat on both sides after slitting, no ragging, to avoid the backing paper breaking when the tension changes. Die-cutting to avoid cutting through the backing paper or damage to the silicone-coated layer, the backing paper and silicone-coated layer is destroyed easily appear backing paper pulled off or the adhesive within the label seeped into the backing paper, there is no label and tear the backing paper phenomenon. In addition, before labeling to eliminate the static electricity in the web label, because static electricity will cause labeling does not come out of the label or the phenomenon of labeling is not allowed.

Understanding the labeling machine requirements of the label, you will be able to avoid a lot of sub-standard labels, warped labels and other common problems.

Shenzhen Changhao Huifeng Industrial Co.

9F, Zhengke Times, No.17, Industrial Road 1, Da Wang Shan, Shajing Street, Baoan District, Shenzhen

Copyright@2023粵ICP備15020808號